#2 bulkead in the bag with rowers footwell side walls and rowers footwell bulkhead support. My original plan was for one sidewall to go to the floor full height and leave the second half size for access under the floor. However my architect buddy pointed out a few flaws in the design...notable that the rowers footwell has no support, and that with that design it would be really hard to get into the "back" of the cavity. So he suggested moving the support to the center to cut the span in half and have two small places under the floor, one in each side hatch. Seems to work really good. Thanks gleason!

Rowers footwell floor in the bag. Nice hefty layup. 3 layers of 8 oz underneath...used scrap since it wont be seen. Lots of 45 degree bias and one layer at 90

On top a layer of 12oz biax over 8 oz cloth, with two more layers of 8 oz on top. It made a super bomber floor. No flexing here.

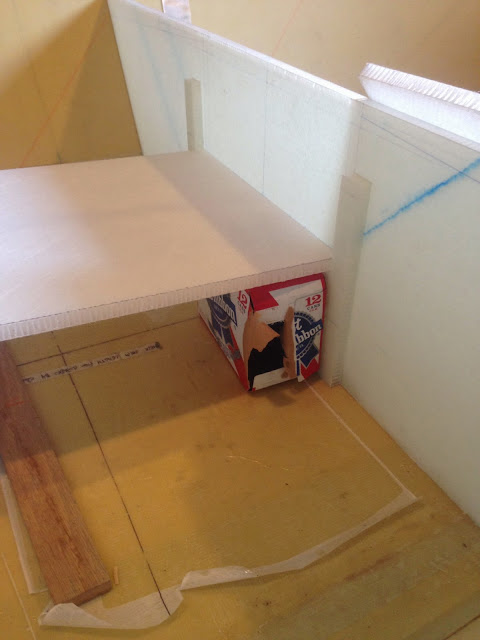

Tacking bulkheads in place. Spreading hatches to have an interior width of 24"

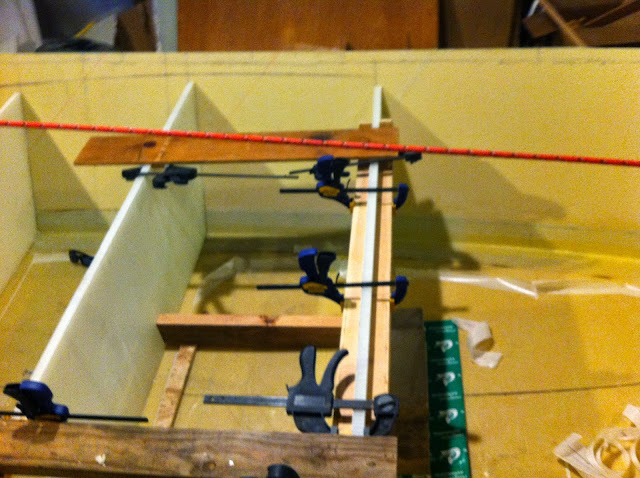

I found out may table wasent quite flate when i laid up the first two bulkheads, so there cured slightly cupped. I clamped tham between 2x4s to straighten them out withey got tacked into place.

My 24" bulkhead speader allows me to easily mark the sidewalls with the bulkheads vertical. Also allow me to clmap things in place

Clamping foam core in place for gutters. Water drains OUT of the boat, not into the footwell. This is one of those things i never understood about the originally designed briggs gutter systems. They move the water down the gutter and into the footwell, then out of the footwell and out of the boat. These gutters drain to a point about 2" below deck height.

These shorter ones are the gutters for the dryboxes. They drain the sides of the hatch lids into the side box gutters about halfway down.

Gluing them all up at once. Sandwiched between saran wrap covered 1x stock

Speaking of beer, can i just say that my new job at the brewpub is awesome!

Glassing the sidebox gutters. This didnt work out the way i planned. No matter how hard i tried with so many pleats it was really hard to get the glass to wrap those hard edges without bridging. I put a visqueen covered piece of 3/4" mdf inside the bag to give a flat surface to clamp down onto. I dont have a table to bag onto and this was an easy fix to the problem. Work good. Ill use this method more for fabricating little parts.

Gutters kind looked like crap with folded and bridged glass. I attacked them with a grinder. Gotta look worse before it can look better. These are salvagable tho. Ill fair em flat. They will get glassed to another plascore side that supports the deck. Then the whole bottom and both sides will get wrapped in glass tape, and the gutter will get a fillet in the corners and more glass tape in the gutter bottom. The only surface that came out good were the tops where the hatch lid lays...which is the most important anyways. This glass does provide a good bit of structure to the foam. For the side gutters i may try to make a top "mold" that will suck down onto the gutter top in the bag with saran wrap sandwiched between instead of bleeder ply. This should hopefully keep the glass where in needs to be.